Brooks saddles: standing the test of time

For almost 150 years, Brooks has led the way in designing and manufacturing leather saddles. It still does so today, producing on average 150,000 a year at its factory in Smethwick, Birmingham.

In 2002, Brooks was taken over by Italian company Selle Royale. Yet while many other firms in the British cycling industry have moved abroad or disappeared altogether, Brooks has remained alive and kicking in the UK. So what’s the secret to its lasting success?

“It starts with the product, the way it’s made and the quality it has,” says Andrea Meneghelli, Brooks’s brand director. “It’s a product of excellence, in terms of design, construction, the materials we use and also in terms of functionality in the way the product works and performs.”

Did you know? John Boultbee Brooks made the first Brooks saddle back in 1865. His father made leather saddles for horses and the young Brooks used his workshop. Today, there are around 60 models of saddle available, and many are the same designs first used by JB Brooks all those years ago.

In 150 years, bikes have changed radically, but Brooks saddles have remained constant. Much of the machinery in the Brooks factory dates back to the 1940s, while one of the most popular saddles, the B17, was first patented in 1898.

“I can’t think of many products, even in other industries, that have lasted so long without changing,” explains Meneghelli.

It would be hard to find a cyclist who doesn’t have their own story about a Brooks saddle, or knows someone who does. Part of the reason for Brooks’s success, says Meneghelli, is its focus on longevity and, as every commuter or long-distance tourist will know, comfort.

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Bag yourself a bargain

Since the company takeover, there have been some changes. Saddle bags are back in production after manufacture stopped around 40 years ago. Brooks also now sells clothing, and accessories such as handlebar grips and leather bar tape, although these are mainly manufactured in Italy and Germany.

The saddle range is expanding too. The Cambium, introduced last year, is Brooks’s first non-leather saddle. Made from rubber, it’s designed to be lighter, without losing comfort. Yet this doesn’t signal the start of a radical change for the company.

“They’re not the lightest saddles on the market, and we’re not going to go down the route of trying to make the lightest one either,” says Meneghelli.

“Maybe one day we’d make a lighter saddle — not to be lighter, but to be more comfortable.” Instead, Meneghelli says: “We’re trying to bring the company into the 21st century while respecting the heritage.”

Did you know? The leather in a Brooks saddle comes primarily from British or Irish cows, via tanneries in Belgium and Sweden. All the metal comes from British suppliers.

And so, despite being taken over by an Italian company, Brooks remains as British as it has ever been.“For us, it was very important to keep the British identity,” Meneghelli says. In fact, being Italian made it easier for the new owners to identify what ‘British’ meant and keep the legacy going.

“It’s easier for us to see what kind of appeal Britain has, being non-British, maybe that’s something we did quite well,” Meneghelli explains.

Almost 150 years on from when it first began, Brooks has proved change isn’t always necessary. “We’re still making our core product in Britain,” Meneghelli says, “in the way that it was initially conceived and in the way it has always been manufactured.”

Covent garden ‘cathedral’ - Savile Row of cycling

Last November, Brooks achieved another landmark by opening a flagship store — B1866 — in London’s Covent Garden. Nicknamed ‘the cathedral’, as well as stocking the full range of Brooks products, B1866 aims to be more than just a shop.

“It’s important to make a statement that we didn’t open a fashion store, we opened a store for cyclists,” says Andrea Meneghelli. As Stephen Brill, store manager, explains: “We wanted to expand on that handmade bespoke feel that kind of comes with Brooks.”

Saddles can be customised, staff are planning organised rides, and Brooks has collaborated with a number of high-profile bespoke frame builders, so far including Dario Pegoretti, Darren Crisp and Ricky Feather, for special in-store sessions. Customers can book an appointment, talk through their ideas and get measurements taken in store. It all shows that Brooks wants to be far more than a saddle maker.

“The fact that you can go there and make a bespoke bike is due to the fact, we truly believe, that we have cycling DNA,” Meneghelli enthuses. “It’s like going to Savile Row and getting your suit made — we want to be the Savile Row of cycling.”

Test of time

Iconic Brooks products

Thank you for reading 20 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

Founded in 1891, Cycling Weekly and its team of expert journalists brings cyclists in-depth reviews, extensive coverage of both professional and domestic racing, as well as fitness advice and 'brew a cuppa and put your feet up' features. Cycling Weekly serves its audience across a range of platforms, from good old-fashioned print to online journalism, and video.

-

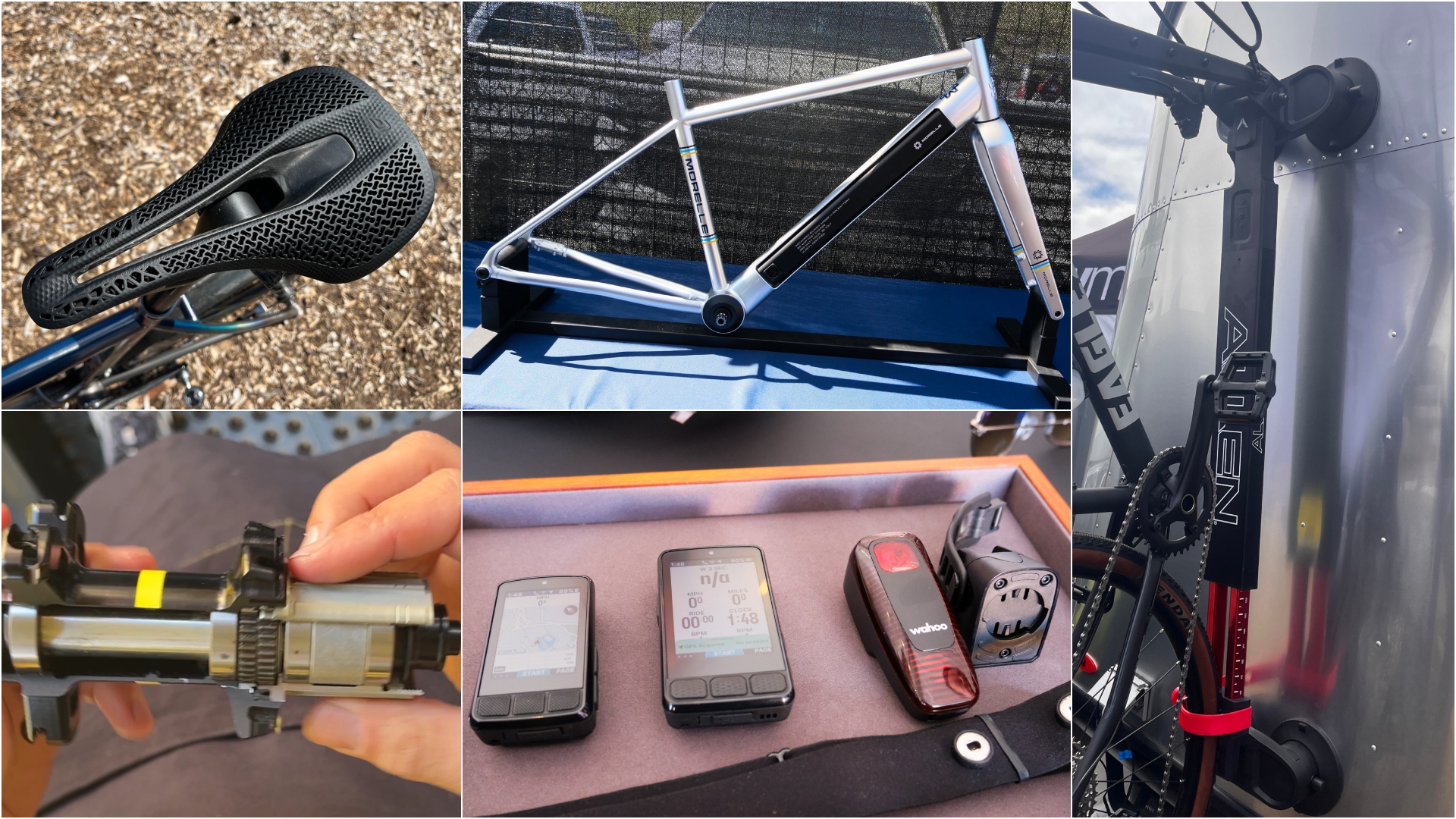

A bike rack with an app? Wahoo’s latest, and a hub silencer – Sea Otter Classic tech highlights, Part 2

A bike rack with an app? Wahoo’s latest, and a hub silencer – Sea Otter Classic tech highlights, Part 2A few standout pieces of gear from North America's biggest bike gathering

By Anne-Marije Rook Published

-

Cycling's riders need more protection from mindless 'fans' at races to avoid another Mathieu van der Poel Paris-Roubaix bottle incident

Cycling's riders need more protection from mindless 'fans' at races to avoid another Mathieu van der Poel Paris-Roubaix bottle incidentCycling's authorities must do everything within their power to prevent spectators from assaulting riders

By Tom Thewlis Published