Covid, Brexit and the UK bike industry: what next for 2021?

With the UK hit by new Covid restrictions and a no-deal Brexit looming we could be looking at more component shortages and price rises in 2021 – but is there cause for longer-term optimism?

Nearly 10 months after the first lockdown the cycle industry is still struggling to catch up with the bike boom.

Back in March, furloughed workers, traffic-free roads and glorious sunshine got the whole world riding bikes, whether they were bought new or dug out of the garage and serviced by the local bike shop.

But the boom took the industry by surprise. Retailers ran out of stock very quickly and with the Far East factories in lockdown there was no prospect of a restocking any time soon.

Guy Pearson, who runs London’s Pearson Cycles with his brother Will, remembers: “On the announcement of lockdown on March 23 we were ready to close the doors like everyone else. But it was only the next morning when the list was published of essential shops to remain open and bike shops were fourth on the list behind chemists. Bike shops?! We’d already told everyone not to come in but that morning it was like quick, get the doors open and get everyone back in.

"The first big run was turbo trainers. We sold any turbo trainer we could get our hands on, even rusty ones that had been in people’s gardens. The entire stock in the UK went in about a week. Then the phone rang all day, have you got any exercise bikes, any turbo trainers? Then we sold out of bikes – every bike we had.”

Enigma Bicycle Works managing director Jim Walker’s experience was similar: “We sold everything we had, which then raised all sorts of challenges. But we managed to cope and we’ve had a very strong year, like everyone in the business.”

However, Walker says that while Engima had forward-ordered most of its tubing and groupsets, getting hold of individual parts is now proving problematic, leading to delays in getting bikes to customers: “We build a lot of custom bikes and customers specify what they want, which is one of the beauties of custom. But when there are particular parts, just something like mudguards, if we haven’t been able to get hold of them then we haven’t been able to complete the bikes.

"Product shortages have been a major issue. Particularly the last couple of months. You add into that port delays. For the last few months we’ve had tens of thousands of pounds worth of bikes that we haven’t been able to complete because we’ve been waiting for a seatpost or a saddle or whatever and that’s been hugely frustrating.

“That’s still going on but we’re actually limiting what we offer – just things that we know we can get,” continues Walker. “We’re just adapting, which is what you have to do.”

Container port blockages

Neil Robinson, an e-commerce consultant who has most recently been working with the Institute of Export preparing companies for Brexit, explains what’s behind the shortages and delays for the UK: “In terms of Brexit, tariffs and getting things through UK ports, it’s going to be the same problem for everybody. There are stories everywhere of companies having frames rerouted to Stockholm or somewhere ridiculous because the ship cannot dock in the UK because the ports are so full of containers.”

Robinson also points to the fact that manufacturers in the Far East are still catching up after the first lockdown. “You’ve still got this underlying issue which is waiting for the raw materials and manufacturing to catch up with the orders that have been put in. The scale of orders that have been put in across the industry worldwide to single suppliers like Shimano as an example… it will be a really patchy kind of stock availability across the board.”

>>> Why do so many 2021 bikes cost upwards of £10K?

Framebuilder Richard Hallett of Hallett Handbuilt Cycles explains how the situation for him could be much worse than for bigger companies such as Enigma. Whereas Enigma forward-orders tubing and groupsets based on the previous year plus an expected percentage increase, the individual frame builder only buys in small amounts. “I only tend to order tubing for two or three frames’ worth in advance but no more than that. I’ve got £5K’s worth of raw materials in my barn, which is a fair amount of money to put into something if you’re a sole trader – and when you don’t know exactly what a customer will want.

“The last bike I built, a shiny stainless steel thing, it took me about a month to get hold of all the parts for it because they were so scarce. A lot of the parts I ended up using weren’t the ones the guy originally wanted. He wanted everything silver and there seemed to be a shortage. He had to have Campagnolo Record carbon levers because you couldn’t get silver Athena. So you spend an inordinate amount of time chasing components and you can never charge for the amount of time you spend looking for stuff.

“I think component shortages are going to be the story of next year as much as this year,” Hallett predicts. “You haven’t noticed it so much this year because retailers have been plundering their stock and selling off what they’ve got. But until these stocks have been replenished, it will be harder and harder to get hold of stuff and that’s a problem for everybody, no matter what level you’re at.

“Even middle stuff like Shimano 105 is hard to get hold of. You go on Madison’s [Shimano’s UK distributor] B2B website and they say for example that the next delivery of 105 chainsets in 175mm won’t come in until next year. Madison are constantly running out of stuff. Last time I looked there were some delays for a couple of months.”

'Trends of shortages'

When we contacted Shimano, they declined to comment, explaining that as a stock market-listed company it had to be careful about talking about future trends, with its quarterly reports the only statements it would give. Shimano’s Q3 report does indicate a general cycling boom, however, although it does note that “as the inability of supply to keep up with the rapid increase in demand continued, each country saw trends of shortages in distributor inventories.”

Decathlon's cycling market leader Peter Lazarus foresees these shortages of Shimano components continuing through 2021 simply because it takes time to expand a company such as Shimano’s production capacity. “Manufacturing plants only have a certain degree of elasticity in their production lines. You can only react with the production plants you have and with the people that you have. There will be a fixed number of groupsets this year. This will be linked to the capacity of Shimano, because they haven’t built more factories this year. You can’t build a factory just like that – it can take two or three years. But the bike component brands are communicating with their customers regarding production capacity and are asking for frequent forecasts to be able to invest – or not – in additional production capacity over the coming years, not this year. The word on the street is that it’s a long lead time for parts and production.

"And with Covid there are restrictions in terms of shift patterns, people working per shift in factories. The truck drivers have restrictions too. Then everybody is part of the process from production through to retail. Every little bit is important to the supply chain. If you break the chain there is no supply. So you really have to manage that exceptionally well and it’s bloody tough."

However, Lazarus is adamant that Decathlon hasn't experienced 'shortages' as such: "The perception is that people don’t have stock. We have had stock but it’s just gone so quickly. The speed of sale has been the biggest challenge. We receive a shipment of bikes coming from our factory in Lille or in Portugal. They’re put into stock on Monday and by Wednesday everything will have been sold. We did produce more bikes than we’d forecast for the year."

SRAM reports a similar scenario: “We have a well developed supply chain, so we’ve been fortunate,” says vice president of sales John Nedeau. “We’ve largely been able to handle the demand with a few exceptions – so not significantly impacted by shortages. But, broadly, demand continues to outpace capacity."

Nedeau explains that at the moment bikes arriving to retail are immediately bought and that inventory is not growing at retail or on warehouses, and demand crosses all price points and categories: "By May it was apparent that demand at retail was beyond what anyone could imagine and plan. The orders came back and then grew well beyond normal planning. It’s been that way since that time and we continue to expand capacity to try to satisfy the demand."

Brexit tariffs

Pre-Brexit stockpiling is one of the reasons behind the problems at UK container ports, but what effect will Brexit have on prices of bikes and cycling-related goods?

“Brexit is not a major issue for us,” says Walker. “We don’t buy much from the EU. We sell a lot of bikes to customers in the EU so that will be a challenge in itself, but as far as products procurement is concerned most of our stuff comes from the Far East or the US.”

Decathlon, however, buys its bikes from within the EU, which will be subject to tariffs. "Brexit has a far bigger long term implication for us," Lazarus explains: “We purchase our bikes from Lille, Portugual, Romania, Italy and Poland [although the frames and components are made in the Far East]. Not many big brands do that. They might buy fully assembled bikes from Bangladesh, Sri Lanka or other assembly areas of the world, or from the USA. So there will be an additional tariff on goods we import from the EU.

“Whichever tariffs there are we’ll do everything we can to absorb them in our business model. But in order to be profitable we will frequently have to evaluate and revise our pricing model. The fair price will have to reflect the fair costs that we will incur. And whichever costs they are, we will fairly pass that on to the consumer depending on what the government agrees with the EU on import tariffs. If tariffs are removed we’ll reprice accordingly.”

Lazarus says Brexit hasn’t affected French brand Decathlon’s desire to continue trading in the UK and it has just opened a new warehouse in Northampton. Besides, “trade negotiations never end,” he says. “People expect us to have one deal and walk away without ever talking to the EU again. That’s not how the world works. There will be continual trade deals taking place for evermore.”

Exchange rate effect

But what bike brands both large and small see as the biggest problem is the exchange rate.

Hallett identifies the “inevitable tanking of the pound that’s coming our way. It’s likely the pound will be on parity with the euro in three months’ time. So that’s almost a 10 per cent increase in prices straight away.”

Lazarus goes further: “The big problem is the volatility in both directions. If you’re going too far in one direction, drop the prices and your model changes, then suddenly prices go back up again, you can’t forecast your investment as well. Your margin might drop one month and not the next. Exchange rate is our biggest worry in the long term. That’s the biggest element in our pricing. We can’t sell at a loss.”

However, although it seems like a fairly bleak picture for 2021, there’s a lot of optimism for the bike industry in the longer term. Walker concludes: "I think to summarise it, for the industry it’s looking hugely positive beyond 2021. The bicycle has got everything going for it. With global warming, emissions, traffic gridlocked… all of those issues have got to be addressed and the bicycle is a simple solution for humanity. You add in the obvious health benefits. The bicycle has got everything going for it and I think the future can only be very, very rosy for our industry."

Lazarus agrees: “We’re fortunate that we’re en vogue and for a change we’re a sexy industry to be in. We’re not lawn mowers or vacuum cleaners, we’re bikes. We’ve seen the Strava report about the uptake of female cyclists and we’re not making big dirty 4x4s. Let’s celebrate that we’re in a good position to keep going. Let’s celebrate that demand was so high, people wanting to cycle because it’s a great activity, a great sport. It bodes very well for the future in the mid to long term but it’s going to be a painful 2021."

Thank you for reading 20 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Simon Smythe is a hugely experienced cycling tech writer, who has been writing for Cycling Weekly since 2003. Until recently he was our senior tech writer. In his cycling career Simon has mostly focused on time trialling with a national medal, a few open wins and his club's 30-mile record in his palmares. These days he spends most of his time testing road bikes, or on a tandem doing the school run with his younger son.

-

Marianne Vos signs career-long 'forever' contract with Visma-Lease a Bike

Marianne Vos signs career-long 'forever' contract with Visma-Lease a BikeFormer world champion becomes team's second rider to pen indefinite deal

By Tom Davidson

-

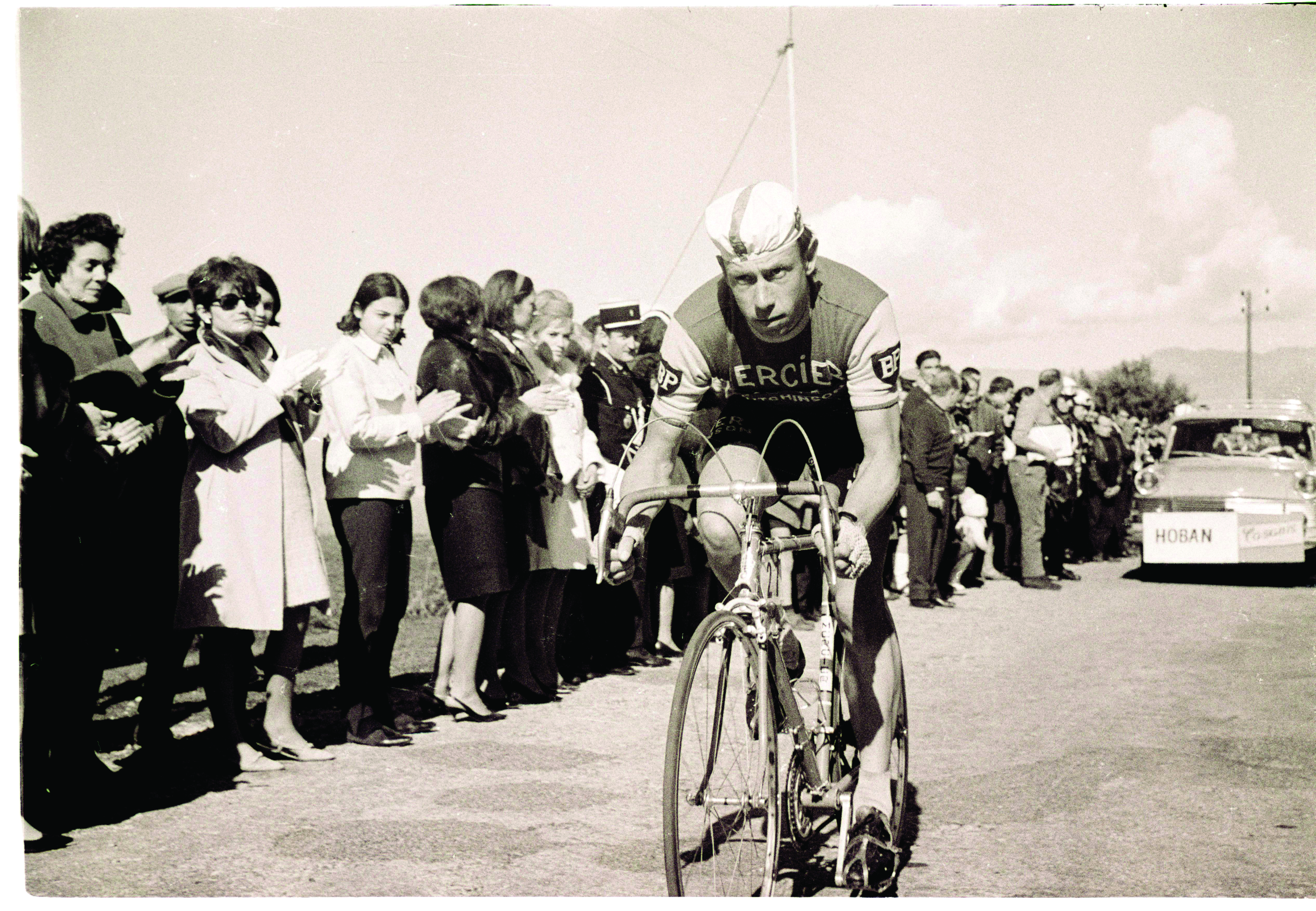

British cycling legend Barry Hoban dies aged 85

British cycling legend Barry Hoban dies aged 85Eight-time Tour de France stage winner paved way for future British success

By Adam Becket