New Shimano Dura-Ace R9200 and Ultegra R8100 launched with semi-wired, 12-speed shifting

The arrival of the new Shimano Dura-Ace groupset comes alongside a new Shimano Ultegra R8100 platform

Shimano Dura-Ace R9200 has been five years in the making - one year longer than the usual product cycle. Its arrival follows an intense period of speculation, spy shots and secret patents - but the Japanese component manufacturer has finally revealed the all-new 12-speed, semi-wireless groupset.

Not only that, but Shimano has taken the highly unusual step of launching its new second string road bike groupset, Ultegra R8100, simultaneously. In the past there’s been a gap between the release of the top groupset and the next one down, hence the term ‘trickle down’ - but this time Shimano has poured the same technology into both.

For the first time there will be no mechanical-shifting Dura-Ace option, and the same goes for Ultegra. Both are Di2 only, but it’s a new Di2 platform that uses wireless shifters, with brand new derailleurs wired to a central battery in the seatpost.

However, both groupsets have rim-brake options - possibly reflecting Team Ineos’s high-profile reluctance to switch to disc brakes.

Those are just the headlines. Shimano is also promising its fastest and most reliable shifting ever, improved aerodynamics, incredible stopping power, the most advanced drivetrain yet and a redesigned wheel line-up.

What it’s not promising is lighter weight: it seems to have called a truce to the race to be lightest, with the new Dura-Ace R9200 groupset 35g heavier than than the previous generation. The new Ultegra is 300g heavier than the new top-flight groupset (and 11g heavier than the old version) but, as is traditional, costs around £1,000 less than Dura-Ace depending on the exact spec.

Shimano Dura-Ace R9200 and Ultegra R8100 tech specs

Shimano has broken the new Dura-Ace and Ultegra groupsets down into chapters: shifting platform; control interface; brake system; drivetrain system and wheel system.

This section discusses, primarily, the 'what' - for the 'why' and our analysis, click the navigation link for the deep dive on development.

Shimano Dura-Ace 9200 and Ultegra 8100: shifting platform

Shifting on Shimano's new Dura-Ace groupset is a reported 58 percent faster at the rear and 45 percent faster at the front

“Fastest-ever shifting, absolute reliability, integrated design” are what Shimano is promising with its completely revised Di2 platform.

To improve shifting speed whilst making the shifter-derailleur connection wireless, and still ensuring reliability, the new Di2 platform brings an improved motor design in the derailleurs, which Shimano says decreases the processing speed - the moving time between motor and gear mechanisms, and the transmission performance.

The result is a claimed 58 percent decrease in rear derailleur operating time and a 45 percent decrease in front derailleur operating time.

Shimano says the “absolute reliability” is provided by a wired connection “where it makes sense” - that's the explanation for why it hasn’t gone fully wireless, SRAM style.

New smaller-diameter SD-300 wires connect a new Di2 battery located in the seatpost as before to the front derailleur and rear derailleur.

The rear derailleur houses the 'brain' on new semi-wired Shimano Dura-Ace and Ultegra groupsets

According to Shimano this single internal battery ensures a stable and high voltage connection to the derailleurs, contributing to the brand’s fastest-ever shifting.

The BT-DN300 battery lasts a claimed 1000km between charges while the CR1632 coin cell batteries that power the STIs last for approximately 1.5-2 years according to Shimano’s testing.

A fully wired option is also available - and for the rim-braking STIs this is the only option, which means that if Ineos stick with rim brakes they’ll also be sticking with fully wired Di2.

The rear derailleur is the star of the new Di2 show. It’s the point at which the system is charged (replacing Shimano’s SM-BCR2 charger), it provides the connection to the STI shifters via Shimano’s proprietary integrated circuit, the ANT+ connection to other third-party devices (replacing the EW-WU111 wireless unit), and it also replaces the handlebar or in-frame junction box A.

Where the Ultegra derailleurs differ from Dura-Ace is in the construction, with functionality the same. The R9200 front and rear derailleurs weigh 96g and 215g respectively versus R8100 weights of 116g and 262g, resulting in a combined 67 g difference.

Shimano Dura-Ace 9200 and Ultegra 8100: control interface

New Shimano Dura-Ace shifters (left) against a set of outgoing shifters - in this case, Ultegra Di2, but these were idenical to Dura-Ace Di2 in size

New, larger shifters

Unfortunately, our test bike was damaged in transit, with a cracked (and proprietary) handlebar ruling out riding, so our ride impressions will have to come later.

Whilst we couldn’t ride our test rig, we could directly compare the shifters - an image side by side shows they’ve clearly grown in volume, and riders who did experience that disconcerting feeling of almost diving off the end on broken sections of road will be pleased with the update.

For the ‘control interface’ Shimano is claiming “unparalleled ergonomics and clean cockpit, customisation.”

The new 2x12-speed wireless hydraulic disc brake shifters now come with a raised head portion with a slight inward curve and increased area between the shifter and the handlebar to bring what Shimano is calling “new levels of comfort and control”.

This bigger grip area aims to give a better three-finger grip behind the brake lever, while still offering easy access to the shift lever in the drops.

Shimano has also increased the offset between the Di2 buttons on the lever, allowing for better differentiation between the upshift and downshift button, especially useful with full-finger gloves.

As for control customisation, E-Tube Project version 4.0.0, updated for R9200 and R8100, as before can offer Synchronized or Semi-Synchro shifting, Multi-Shift, shifting speed and STI shift button mapping to be set up via the app. Also as before, connections with third party cycle computers can all be set up here to display Di2 information.

Again, small differences in the construction account for a weight difference of 32 g between ST-R9270 shifters (350g) and ST-R8170 shifters (391g).

Shimano Dura-Ace 9200 and Ultegra 8100: drivetrain system

Shimano has included new, larger chainring sizes along with 12-speed shifting at the rear

“Optimised drivetrain components, quick and shockless shifting, integrated power meter” are the sub-headings here. Shimano says it has set a new benchmark for performance in these areas.

The new 12-speed Hyperglide+ cassette still starts with the 11t sprocket rather than a 10t, as SRAM’s latest 12-speed system does, instead plugging a gap in the ‘sweet spot’ gears between the 6th, 7th and 8th sprockets. This means that an 18t sprocket can now be included.

There are just two Hyperglide+ cassette options with the same ratios for both Dura-Ace and Ultegra; 11-30t and 11-34t ratio, offering a 1:1 ratio with Dura-Ace for the first time. We can probably expect to see a closer-ratio 11-28t announced later for racing.

The cassettes come with a new spline pattern which is backwards compatible with 11-speed freehub bodies, meaning new 12-speed cassettes can be used on the previous 11-speed wheels. However, the new freehub bodies on the new 12-speed wheels are not compatible with 11-speed cassettes.

The 12-speed cassette narrows the jumps between gears at the centre of the block

As well as the new wider-ratio 11-34 Dura-Ace cassette, at the other end of the spectrum for Dura-Ace comes a new, bigger 54/40 chainset option to replace the classic 53/39, offering higher transmission efficiency than smaller chainring options according to Shimano - a better chainline at high speeds in other words, but also responds to pro riders’ ever-increasing speeds.

As for the chainset, there are two options for both groupsets: the integrated power meter version or the non-power meter version. Both are aluminium and feature Shimano’s Hollowtech II manufacturing technology, and come in either 50/34, 52/36 or the new 54/40 chainring combination (Dura-Ace only), in crank lengths from 160 to 177.5mm and with a Q-factor of 148mm.

The power meter versions use both Bluetooth and ANT+ protocols, have a claimed 300+ hours of ride time between charges and come with an improved 1.5% strain gauge accuracy.

The new chainset uses the same 12-speed chain as Shimano’s mountain bike XTR M9100 series and for Ultegra XT M8100.

Ultegra power meter and non-power meter cranksets come in either 50-34T or 52-36T gear combinations with crank arm lengths of 160, 165, 170, 172.5 and 175 mm. The power meter crankset - the first for Ultegra - weighs 769g, which is 21g heavier than the Dura-Ace power meter at 748g.

Shimano Dura-Ace 9200 and Ultegra 8100: brake system

Shimano Dura-Ace rotors are now the same as Shimano XTR rotors - which offer better heat dissipation, the pads have also been moved outboard

Not quite new XTR rotors

New Dura Ace uses XTR rotors, borrowed from Shimano’s mountain bike groupsets. The pros had already been using them as they offer greater heat dissipation (66 percent, according to Shimano) and are lighter, too. Ditto, in personal builds CW’s Tech Editor has opted for the same set-up, and can confirm it’s a wise choice, so to an extent, Shimano has been led by user choices here.

“Finest control ever, quieter system, maintenance-friendly” are this section’s headlines. The new brake components borrow Servo Wave technology for the brake levers, taken from its mtb and gravel braking systems. This is aimed at giving riders a shorter free stroke meaning a more immediate connection between brake pads and rotors, allowing for better modulation and more confidence in technical situations.

Shimano says brake noise reduction has been improved through 10% wider brake pad and rotor clearance and a switch towards Shimano’s RT-MT900 rotors for Dura-Ace - the XTR mountain bike version that some pro teams were already using with the previous groupset. Meanwhile, Ultegra will use the already-existing RT-MT800 XT mountain bike rotor rather than introducing its own.

When Shimano says ‘noise reduction’ we have read into that ‘rubbing reduction’: the MT900 rotors are a claimed 66% more resistant to heat deformation than the earlier Dura-ACE RT900 rotors.

Shimano also claims brake maintenance has been improved, and that now it is possible to bleed the brake without removing the caliper from the frame thanks to a separate bleed port and valve screw.

The Ultegra brake calipers weigh 282g per pair versus the Dura-Ace weight of 229g.

When we went to press we had no information at all about the rim-brake versions.

Shimano Dura-Ace 9200 and Ultegra 8100: wheels

The Japanese brand has released three new Dura-Ace wheels, as well as a new line of three Shimano Ultegra wheels

“Aerodynamics, driving rigidity and lighter weight” were Shimano’s objectives in its redesigned wheel line-up for both Dura-Ace and Ultegra, with the new line-up including the first full-carbon disc-brake range at Ultegra level.

For Dura-Ace there’s a new ‘Direct Engagement’ hub, which uses two interlocking faces rather than a pawl and ratchet system, and a lighter weight rim construction, both of which are applied to carbon tubeless and tubular options in three rim depths (there’s still no Shimano carbon clincher). This is the first time Shimano has made a full-carbon disc brake wheel range at Ultegra level.

There are three rim depths, with C36, C50 and C60 models at both Dura-Ace and Ultegra level.

The new Dura-Ace C50 in particular excels drag reduction according to Shimano, supplying a 5.1W drag reduction in race situations versus the pro-favourite R9100 C40 wheel and a 1W reduction versus the deeper R9100 C60 wheel, while also being 161g lighter than the C40.

Shimano Dura-Ace R9200 and Ultegra R8100: weights, prices and availability

New Shimano Dura-Ace is marginally heavier than the groupset it replaces

According to Shimano’s figures, the new Dura-Ace groupset weighs a total of 2,438g with the regular non-power meter chainset, compared with the 2,403g of R9100 (again non-power meter).

Meanwhile Ultegra R8100 weighs 2,716g compared to R8000’s 2,705g.

As for pricing, again it depends on the spec, but with the power meter groupset the list price of a complete Dura-Ace R9200 groupset will be around £4,350 by our calculations. Each individual component is a little more expensive than R9100 (£4,085 at Hargroves when we checked) but it’s not a huge jump in price.

Ultegra we calculated to cost £3,099 with the power meter chainset, maintaining that £1,000-plus gap to Dura-Ace.

Availability is from October 2021.

| Component | Dura-Ace R9100 series | Dura-Ace R9200 series | Dura-Ace R9200 series RRP | Ultegra R8100 series | Ultegra R8200 series | Ultegra R8200 series RRP |

|---|---|---|---|---|---|---|

| Rear derailleur | 197g | 215g | £699.99/$814.99 | 240g | 262g | £379.99/$409.99 |

| Front derailleur | 104g | 96g | £399.99/$449.99 | 133g | 116g | £249.99/$259.99 |

| Cassette (11-30T) | 211g | 223g | £329.99/$359.99 | 269g | 297g | £119.99/$111.99 |

| Chain | 246g | 242g | £56.99/$86.99 | 257g | 252g | £44.99 |

| Crankset (52/36, 170mm, w/PM) | 695g | 748g | £1199/$1469.99 | NA | 769g | £999.99/$1159.99 |

| Crankset (52/36, 170mm) | 624g | 690g | £549.99/$624.99 | 681g | 711g | £299.99/$314.99 |

| Bottom bracket cups | 54g | 54g | £56.99 | 66g | 66g | £34.99 |

| Shifter pair | 320g | 350g | £1199.98/$1537.98 | 360g | 391g | £899.98/$1,073.98 |

| Brake calliper pair | 250g | 229g | Included with STI | 285g | 282g | Included with STI |

| Brake hose | 60g | 60g | Included with STI | 60g | 60g | Included with STI |

| Rotor | 234g | 212g | £56.99/$81.99 | 251g | 212g | £46.99/$55.99 |

| Cable E/W | 39.9g | 14.5g | £24.99 | 39.9g | 14.5g | £24.99 |

| Battery | 50g | 53g | £174.99/$184.99 | 50g | 53g | £174.9/9$184.99 |

| Junction Box A | 6.4g | NA | NA | 6.4g | NA | NA |

| Junction Box B | 4g | NA | NA | 4g | NA | NA |

| Wireless unit | 3g | NA | NA | 3g | NA | NA |

| Total (no power meter) | 2403.3g | 2438.5g | £3,700.99 | 2705.3g | 2616.5g | £2,399 |

Shimano Dura Ace: behind the scenes and development

With Dura-Ace R9200 and - somewhat unexpectedly - Ultegra R8100 having broken cover, we sat down with Mike Anderson, PR manager of Madison, Shimano’s UK distributor, for some background. We put to him questions that we knew prospective new users, as well as long-time Shimano spotters like us, would be asking. For example, why semi-wired and not fully wireless? Why did Ultegra launch at the same time as Dura-Ace? Who will buy Dura-Ace Di2 at its list price of £4K-plus and what makes it cost that much? Is 105 going to go electronic next?

But we started by asking how accurately the cycling media had guessed what was going to be on the new Dura-Ace menu after the multiple patent discoveries of this year and last.

We have been enjoying all the alleged scoops and saying ‘absolutely not, that’s so far off.’

Mike Anderson, Madison UK

“Shimano are always filing patents like they’re going out of fashion because obviously it gives them the intellectual property over [new tech],” says Anderson. “So we have been enjoying all the alleged scoops and saying ‘absolutely not, that’s so far off.’”

Huh. However, Anderson admits that even if some of the wackier ideas, such as the cigarette lighter-inspired piezo electronic shifting, aren’t in this groupset, that doesn’t mean we won’t see them in four years or eight years’ time.

No piezo electronic shifting from Shimano, then

“Shimano don’t file a patent for a laugh,” he continues, “they file a patent because they think there’s a certain feasibility in the idea, and those ideas definitely give you an indication of the way the component manufacturers are thinking.”

Perhaps that explains why the new Dura-Ace groupset doesn’t include anything truly astonishing or groundbreaking. It seems a little… safe?

“The two new groupsets - like all Shimano groupsets - are focused on performance,” says Anderson. He asserts that the performance of these groupsets is genuinely very impressive and if the figures quoted in the press release are accurate he’s correct: Di2 already had the fastest shifting speed on the market and Shimano has improved it by 45 per cent at the front derailleur and nearly 60 per cent at the rear despite going wireless.

“Making communication through a wireless medium as quick as communication through a wire is extremely challenging,” Anderson emphasises.

Wired for options

A semi-wired groupset provides more options

Anderson insists improving shifting speed was a good reason for going with one wire to each mech and not completely wireless. We’d add that SRAM’s patented detachable batteries on its eTap derailleurs may have made life difficult, too.

“Shimano essentially are adapting a technology they already have, which makes sense from a development cost point of view,” he explains. “Dura-Ace is already very expensive to develop, let alone produce. And the wired system with the battery with three ports is an elegant solution that obviously still gives you the option of wiring the whole system should you want to.”

Those using the rim brake version of the new groupsets will have to use that fully wired system since it’s only the hydraulic version that is wireless. Why no wireless shifters for rim braking?

“Shimano are not anticipating anywhere near as much uptake in the rim brake version as disc,” says Anderson. With the market focusing on disc brakes and manufacturers such as Specialized dropping rim brakes altogether on their top race bike, the Tarmac SL7, it hardly seems surprising that Shimano also prioritises discs.

“There will be a lot of people who still want rim brakes but most people won’t,” predicts Anderson. “Especially with Dura-Ace: Dura-Ace is a professional-use product. And in the professional peloton, everybody [bar Ineos] is riding hydraulic discs so the demand isn’t there now.”

According to Anderson every performance element change to the new groupsets including the shape and angle of the hoods and the extension of the shifting paddles and the offset between the buttons comes from teams such as Groupama-FdJ and Lotto Soudal, with whom Shimano works closely. “So if the teams aren’t saying ‘can we have a wireless rim brake version?’ there’s no point in developing it.”

Disc division

There's little point placing much focus on developing rim brake groupsets on a pro level set-up, with so few pro teams utilising the stoppers

We were told by a wheel manufacturer that 80 per cent of new road wheels sold are disc and the rest rim, and that also seems to inform Shimano’s latest direction.

“I think that’s only going to continue,” confirms Anderson. “With a rim-brake carbon wheel every time you brake on it you’re moving it slightly closer to obsolescence whereas with a disc-brake carbon wheel you’re only wearing away the rotor.

“For somebody who doesn’t earn a ton of cash, buying wheels that will last as long as they want them to unless they crash is much more sensible than buying a set of wheels that will eventually wear out.”

Ultegra is at the level where you get all the performance for a little less cost

Mike Anderson, Madison UK

With the new groupsets, not only is there a new line of three Dura-Ace carbon wheels but there’s a range of three new Ultegra carbon wheels, which Shimano has never made before - but still no carbon clincher? “Shimano have never made a carbon clincher for a rim brake,” says Anderson. “They don’t believe in the technology - and they’ve stuck to their guns.”

The new wheels are tubeless ready but not hookless which, in keeping with the slightly conservative new Dura-Ace groupset is exactly what you’d expect from Shimano (there are also tubular versions in Dura-Ace). They are wide but not groundbreakingly wide with a 21mm internal rim width. They’re light but they’re not ridiculously light. Anderson agrees: “They’ll all work well with 30mm tyres but any wider they’re not the ones for that.”

Shimano has highlighted the fact that with the launch of the two new groupsets is the first ever range of Ultegra carbon disc wheels. Why is that a big deal?

“Ultegra is at the level where you get all the performance for a little less cost and now you’ve got the power meter too. That’s a really important thing. It’s reinforcing Ultegra as a legitimate option even for the amateur racer.”

Ratio rationale

Greater chainring sizes are just as much about improved chain articulation over pushing a bigger gear

As for the bigger chainring size with new Dura-Ace (but not Ultegra) we’re guessing it was the pros that also voted to scrap the classic 53/39 in favour of 54/40?

“People think running a larger chainring means pushing a larger gear, but actually it allows for a more efficient chainline,” says Anderson. “You can go up the cassette a bit and get a better flow of the chain. It’s the reason why the current Di2 won’t let you shift all the way down the cassette when you’re in the little ring. You’re stressing the chain.”

However, at the other end the new Dura-Ace does include an 11-34 cassette, a first for Dura-Ace. Previously its maximum sprocket size was a 30t.

“For everyday riding there’s no point in an 11-25,” says Anderson. “Even the pros ride 11-30 in the mountains now. The jumps between sprockets are concerns for time triallists rather than climbers. When you’re riding up a mountain there’s rarely a moment when you’d want to change down but only by a tiny amount.”

The usual thing is that Ultegra comes out after Dura-Ace - that's not the case this time.

"From a consumer point of view it’s really nice to see them come out at the same time and to be able to directly compare them side by side,” Anderson says.

Backwards compatibility

You'll still be able to run your existing wheels with 12-speed cassettes, but the new wheels won't house 11-speed

We had concerns that the new 12-speed groupset wouldn't be backwards compatible, but it seems like it is.

Anderson highlights that the new 12-speed wheels have a new freehub design that is not Microspline, like the 11-speed hubs, meaning that 11-speed cassettes will not fit the new 12-speed freehub. However, all 12-speed cassettes fit existing 11-speed Hyperglide wheels. “It’s a way of making sure everyone has the option of buying a Shimano groupset without having to buy a new set of Shimano wheels. So if you’ve got three grand invested in a set of expensive wheels and a new groupset comes out… obviously that’s a good thing.”

We recall Shimano insisting that the R9170 STIs weren’t too small. Yet the new ones are bigger?

“The pros wanted something a bit larger to press against and grab onto,” says Anderson. “The current R9170 hoods are astonishingly small given that they’ve got a hydraulic housing in them. The pros say they spend a lot of time with our arms down, pressing forward on the bars, and just want a bit more size. So it’s a compromise between the R9170 and the original R785, the big old chunky ones that were the first hydraulic road brakes, and obviously, they’re angled slightly inwards too now, which is an ergonomic change. But that was directly pro rider feedback.”

When will 105 go Di2?

Shimano 105 is unlikely to go lekky any time soon, it seems

What can we expect from 2022? Will there be a 105 Di2? Will mechanical shifting start with Tiagra?

“Currently I don’t believe there will be a 105 Di2. But I would be really surprised if Shimano aren’t looking into it heavily,” says Mike Anderson, PR manager of Shimano’s UK distributor Madison.

He explains that historically the Ultegra and Dura-Ace electronic groupsets are produced in a different facility from the rest of the road groupsets, meaning a significantly larger production would be expected from a factory not equipped for that scale.

“All the Di2 is produced in high-tech clean rooms because you don’t want contamination of any of the electrical components, microchips etc. so that has always been the barrier,” says Anderson.

There’s also profit margins to consider, as Anderson explains: “105 is specced on a huge number of bikes from £1,500 up to £2,800 so you’d need to manufacture it in a huge quantity and still make some money given that you would have to develop the ability to make the wireless tech cheaper.”

There’s also the tooling for aluminium rather than carbon to consider: Anderson notes that since 105 is all alloy rather than carbon there would be a lot of setting up to be done.

“At the moment the quality of Shimano 105 relative to the price is astonishing,” he says. “Maybe more likely is that Shimano are working on 12-speed mechanical for 105. Because the change from a ratchet that shifts 11 times to a ratchet that shifts 12 times is not as significant as trying to rework the whole groupset as electronic.”

Is Dura-Ace too expensive?

With its list price of £4,000-plus, is the latest Dura-Ace R9200 out of reach of the ordinary bike racer?

Dura-Ace has always been a pro-first product, according to Mike Anderson, PR manager of Shimano’s UK distributor Madison, but the huge price hike in the last 10 years is down to changing technologies. However, he says, even at its highest price to date Madison still expects to sell every last Dura-Ace groupset.

But with increasingly sophisticated electronics featuring in almost every household gadget, why is Di2 so expensive?

“The interesting thing is that electronic shifting is cheaper to produce because microchips can be cheaply produced - but it costs an absolute ton to develop,” says Anderson.

“Like with the iPhone it’s the development that costs a lot of money not the manufacturing of it - and that’s why it has to be expensive: because you have to recoup what it costs to pay a lot of very smart people a lot of money to take four years to make something.”

Furthermore, Anderson points out, Dura-Ace is in line with the cost of the top equipment everywhere in the bike industry. The Specialized S-Works Aethos frameset costs £4,500 - almost exactly the price of a new Dura-Ace groupset with the power meter chainset.

Shimano Dura Ace Di2 vs SRAM Red eTap

SRAM's top flight eTap groupset carries an RRP of £3,794/$4,158/€4,118 - vs £4,350 for new Dura Ace. The weights, minus a power meter, come in at 2,518g for SRAM Red eTap AXS vs 2,438 for Shimano Dura Ace Di2.

Cycling Weekly’s tech writer Stefan Abram weighs up the options...

Picking a favourite out of these two groupsets is quite a tough choice – Shimano and SRAM have taken such different approaches that there are great features unique to each.

Starting with SRAM, I do really like the shifting ergonomics, with those great big paddles on each side, and simply clicking right for harder gears and left for easier – it’s hard to go wrong.

The replaceable batteries are really great, too. Although they do have to be charged more frequently, for those occasions when you do forget, you can just swap another one in and still control the rear derailleur. Also, as the shifting is fully wireless, building up a bike and attaching those derailleurs really couldn’t be any more straightforward.

But all that said, on balance, I do think the advantages of Dura-Ace are a little greater.

I really like the use of mineral oil over DOT fluid in the hydraulics – it’s noncorrosive, so I don’t need to worry about getting it on my hands or the paint, and also hydrophobic, so I can keep a great big bottle of it on the shelf and not worry about it taking on water and becoming useless over time.

Regarding the drivetrain, as the smallest sprocket is kept at 11 teeth and paired with larger chainrings, the chain isn’t forced to articulate as greatly and therefore should be a more efficient system. It might not be by much – the gains might be more psychological than mechanical – but that still bears an importance which shouldn't be underestimated.

Finally, the quality of Shimano’s front shifting was already pretty great, but the new Dura-Ace has only continued to build on that. Personally, I’ve found SRAM RED (and Force) to be very sensitive to setup – just that continual reliability from Shimano is quite a draw.

How sustainable is new Dura-Ace?

A claw crane operates beside assorted scrap metal at a metals recycling yard in Paris

With human impact on the environment becoming an increasingly urgent concern, it seems only right to question major manufacturers on their credentials.

Tech editor Michelle Arthurs-Brennan spoke to Shimano, and Shift Cycling Culture director, Erik Bronsvoort. Shift is a not for profit organisation seeking to reduce cycling’s environmental impact.

Though it can be recycled, metal is a major consideration when it comes to cycling’s impact on wastage figures. It's often stated that one of the benefits of higher-end components is that they ‘last longer’. We’ll be clamping down on this assertion, because, well, even Shimano tells us it’s not true: higher-end components aren’t built with long life as the primary driver, rather, performance.

“Shimano components use the best balance of materials and specification choices (including weight, treatments, coatings, finishes, technologies and manufacturing processes) to achieve specific performances. Our products for multi-use categories (eg our Tiagra, Sora, Claris and Tourney road groupsets) are designed as more durable products which need to be replaced less frequently,” the brand told us.

A 12-speed set up means reducing the thickness of metal, but Shimano had an answer for us there: “Following a development in mountain biking in recent years, Shimano’s 12-speed systems include Hyperglide+ technology, which offers smoother shifting under load in both directions (up and down the cassette) putting less stress on the drivetrain and increasing longevity.”

Shimano did hint at developments to come, stating: “We are always looking at product innovations and, when the time is right, we will share new products with consumers. However, we don’t have any information to share on products or technologies not currently in our line-up.”

Bronsvoort, who also founded Circular Cycling, told us: “Shifters and other parts of a high-end groupset have been designed and manufactured for performance: shifting speed and weight. Not for longevity, easy repair and compatibility with previous or future generations. They usually wear slowly in one or two areas – the rear derailleur and shifter.”

In terms of future planning, Bronsvoort was skeptical, “designing products that use less materials and thus have a lower environmental impact, requires a whole new design approach. The entire cycling industry has been focusing mainly on performance. To design more sustainable products, designers need to be challenged to combine performance with design for long life, easy maintenance and repairs, compatibility, and using less and the right materials: non-toxic, from renewable or recycled sources and renewable or recyclable at the end of the lifetime. It will complicate the design process. But making sustainability a core part of the job, it will motivate design departments like never before.”

Batteries are another area for discussion. In the automotive world, electric cars are seen as a positive alternative to engines using petrol or diesel - but the production and disposal of batteries is the stumbling block. In the case of groupsets, there's no obvious saving: a move to electronic options simply means more batteries in the world.

“[Shimano’s batteries] are manufactured at Shimano factories in Asia. The product life span of a battery is determined by its storage, the quality of the battery cells and the number of charge cycles. Shimano Di2 batteries last anywhere between 2,000 to 5,000km depending on how many times you shift. In most cases, batteries outlive the average lifetime of bicycle ownership,” was Shimano's response.

Bronsvoort’s more descriptive approach told us: “Batteries are one of the crucial items in a low carbon world. That does not mean a battery should be in everything. Mining resources and producing batteries, and E-waste are a major problem that needs to be solved in order to realize electrification of our power system on a large scale.

“Ideally, the manufacturers would be responsible for making sure batteries last as long as possible, and at the end of the life time, take them back for reuse or recycling. Batteries would not be something a rider would actually own, but pay for as a service and return to the manufacturer when they are broken or not in use anymore.”

History of Di2

The first Shimano Dura-Ace Di2 groupset was launched in 2009. It would be convenient to be able to say it created a ‘buzz’ or ‘sent shockwaves’ through cycling but in fact Mavic had experimented with electronic shifting through much of the previous decade with its Zap and Mektronic systems and had achieved considerable success with Chris Boardman, who won two Tour de France prologues with it.

The Mavic components were incredibly ambitious - Mektronic was even wireless - but, a bit like the Apollo space program, they were a little too advanced for the available technology of the time and were costly and unreliable.

By 2009 the Apple iPhone had already been around for two years and the world should have been ready for Shimano’s electronic shifting system but memories of Mavic still persisted - even though the French brand had pulled out of groupset manufacturing altogether by then. What was the point of reviving a failed system? If it’s heavier than the mechanical version what’s the reason? It’s too complicated. It’s too expensive. Those were the common objections to the first Digital Integrated Intellligence (Di2) groupset, R7970, which cost just over £1,700 – an outrageous amount by the standards of the day.

However, its performance shaded all of that. It was clearly the future of shifting and Shimano’s sponsored pro teams were using it. It received rave reviews - including by us.

Flawless though 10-speed 7970’s performance was, it had an external battery that stuck out under the down tube, a junction box strapped underneath the stem - aesthetically it couldn’t match the beautiful, polished silver of the 7800 groupset before it or of the newly sleek 7900 mechanical groupset that for the first time had its gear cables concealed.

By 2012 and the release of Dura-Ace Di2 9070 those issues had been addressed: there was an internal battery, frame or handlebar-mounting options for the junction box as well as things that Di2 users didn’t even know they were missing yet: E-Tube software meant the buttons were no longer ‘dumb’ - they could be programmed and customised.

The Di2 buttons themselves were easier to use - larger and wider spaced. The original Di2 was not as intuitive as it might have been for long-time users of mechanical STIs. Now you didn’t need to glance at your fingers to make sure they were on the right button.

Both electronic and mechanical 9000 groupsets were now 11 speed.

The following year, 2013, the first Ultegra Di2 groupset was launched. In time honoured trickle-down tradition it had the same four-arm chainset as well as the same electronic platform of Dura-Ace Di2 but wasn’t just a Dura-Ace lite: it had two rear derailleur options so that riders could use a 32t sprocket. Electronic shifting for the people was finally here.

2016 saw the launch of Dura-Ace R9150 and was the first Dura-Ace groupset to include hydraulic disc brakes in the series - called R9170.

Synchronized Shifting was also introduced, widening the groupset’s programmability.

Meanwhile there was a new Shadow rear derailleur that allowed sprockets up to 30t and Dura-Ace’s own power meter chainset was also introduced.

Following the traditional pattern, Ultegra R8070 arrived in 2017, again offering all the benefits of the flagship groupset but at a much lower price point for a negligible amount of extra weight. As usual it shared the same electronic hardware and software, arguably edging closer to the performance of Dura-Ace than ever before.

Shimano launched two GRX gravel groupsets in 2019, with GRX800 Di2 the flagship version. Available in 1x or 2x, the Di2 STIs were quite different from the road versions with reworked brake lever ergonomics and hoods reshaped for rougher riding.

It’s fair to say Di2 has been a game changer and it silenced its doubters years ago. These latest 2021 groupsets, despite the shifters going wireless, represent an evolution rather than a revolution, but over the last 12 years Di2 has made small but significant steps with each release rather than risking giant leaps. If R9270 and R8170 are better by the same increments we’ll have a couple of incredibly impressive groupsets at our fingertips.

Thank you for reading 20 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Simon Smythe is a hugely experienced cycling tech writer, who has been writing for Cycling Weekly since 2003. Until recently he was our senior tech writer. In his cycling career Simon has mostly focused on time trialling with a national medal, a few open wins and his club's 30-mile record in his palmares. These days he spends most of his time testing road bikes, or on a tandem doing the school run with his younger son.

-

Unreleased wheels, monster chainrings, and surprisingly skinny tyres: Six tech insights from Paris-Roubaix

Unreleased wheels, monster chainrings, and surprisingly skinny tyres: Six tech insights from Paris-RoubaixHere's all the tech mods we spotted at the men's 'Hell of the North'

By Tom Davidson Published

-

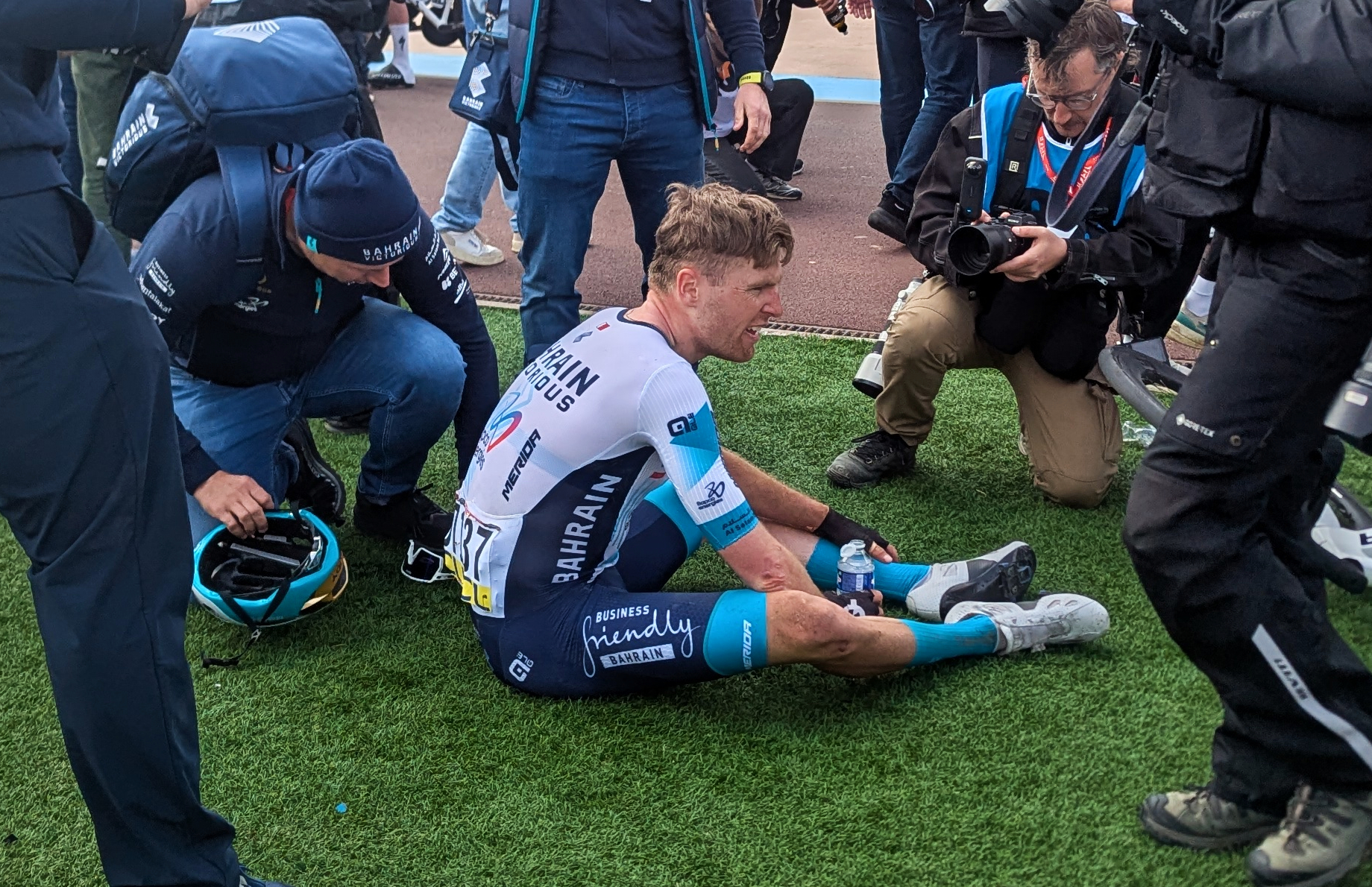

'I'll take a top 10, that's alright in the end' - Fred Wright finishes best of British at Paris-Roubaix

'I'll take a top 10, that's alright in the end' - Fred Wright finishes best of British at Paris-RoubaixBahrain-Victorious rider came back from a mechanical on the Arenberg to place ninth

By Adam Becket Published