Five road bike tech trends I wish didn't exist

From shoddy quality control to steering stoppers, former mechanic and CW Video Manager Sam vents his frustrations

In a world where there are hundreds of road bike manufacturers, there will of course be some road bikes that may not meet the needs of the consumer. From odd spec decisions to bizarre views on pricing, here's a list of five tech trends that I wish just didn't exist.

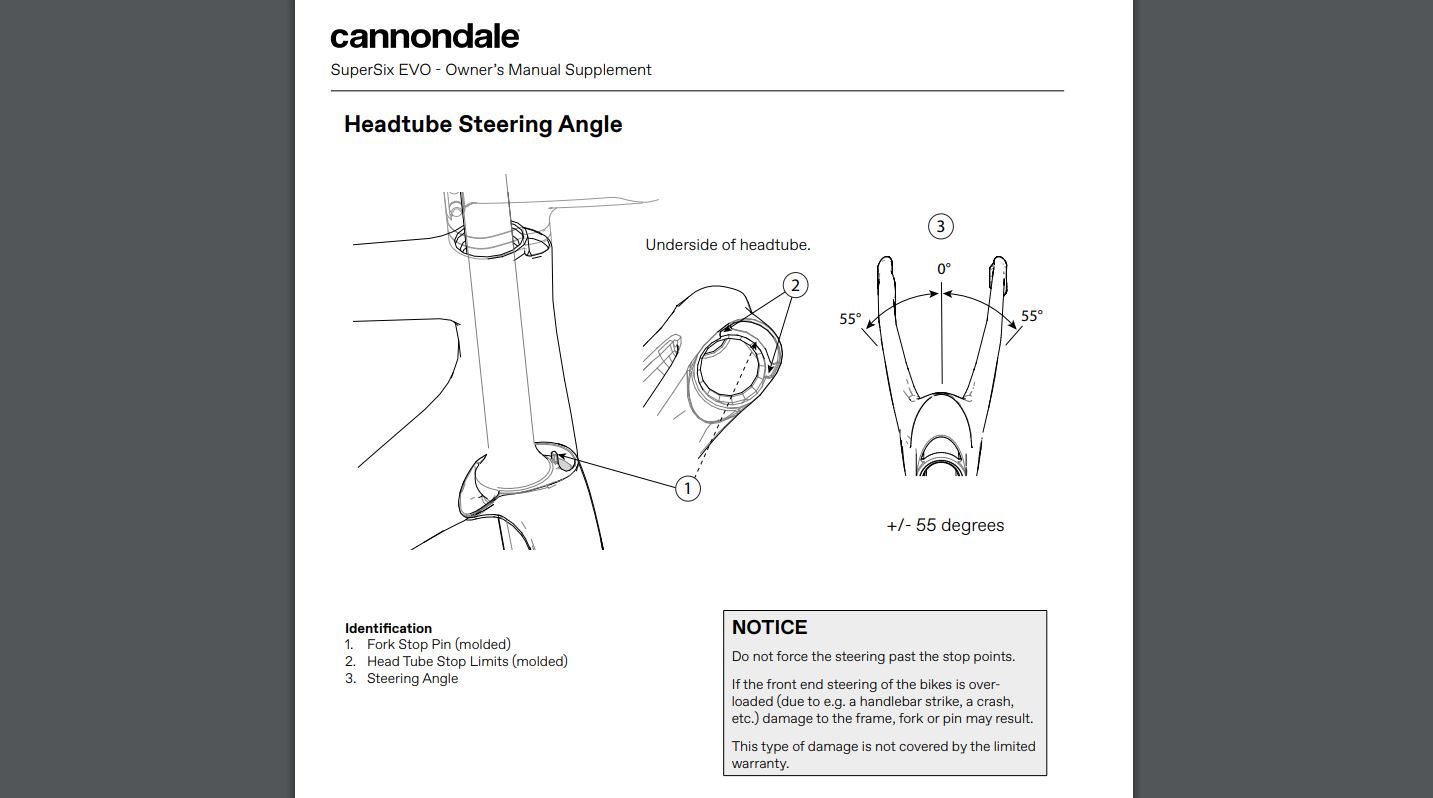

Bikes with steering stops

Frame stoppers on the Cannondale SuperSix Evo didn't hang around

The same generation of bikes that enjoy integrated cable routing, disc brakes and fancy carbon shapes seem to have a few occupants that also play host to steering stops. If you’re unaware, steering stops are a mechanical feature often found within the head tube which stop the bars from turning after a certain point.

The theory is, that by stopping the bars from turning excessively, you reduce the risk of causing damage to the brake lines, and you also stop the potential for the handlebars to swing into your top tube. However, there is a reason why steering stops have been included on this list, and that’s because I have seen multiple cases of handlebars being turned with such force that the steering stops have then ripped through the frame - essentially killing it.

Now, this rarely happens through normal riding. But, it can happen when the wind catches the front wheel when the bike is leant up and stationary or when you’re putting the bike in the car and the fork catches on something, or, perhaps an overzealous mechanic may yank on the bars slightly too hard and causes some accidental damage.

Happily, some bikes that did adopt steering stops are already starting to ditch them. For example, the 4th gen Cannondale SuperSix lost them after they were debuted on the 3rd generation of the bike. Also, as integrated cockpits evolve and cable routing methods improve, the positioning of hoses can be threaded in ways that mean that ‘over steering’ won’t damage the hoses.

My view on this is quite simple. Steering stops should just be a flash in the pan of bike tech trends and hopefully, in the next few years, will eventually disappear. Too many bike frames end up having to be warrantied after innocuous accidents. I’m sure that as the manufacturers start to realise how much money the steering stops are costing them, they’ll be as fast to remove as they were to install. Certainly one ‘innovation’ to forget.

Bikes which are too cheap to be good

Buy once, and buy well - it's kinder to the planet, and your riding intentions

We recently made a video about the biggest false economies in cycling, and in that video I discussed the recent upsurge surrounding the incredibly cheap bikes that can be found at big generic retailers. I’m sure that to some, these bikes will serve a purpose. Especially for those who don’t want to, or can afford to, spend any more money on a bike.

However, I’m a strong believer that you'll ultimately have a better riding experience if you spend the same amount of money - but on a second hand bike instead. You’ll get something that originally costed much more, you’ll be giving a bike that already exists a new lease of life and should you have any issues, most bike shops will be able to help you out.

I believe that these cheap bikes are awful for the environment. Bikes are supposed to last for many years, but the way these bikes are constructed and the components that they’re kitted out with, mean that you’re essentially buying a disposable bike and one that will only last for as long as the rider can bare to put up with its problems.

In my opinion, these bikes should not exist, and we should all be buying second-hand when we can - especially if monitoring cost is a large contributing factor to your purchasing decision.

Bike that cost more than the sum value of their parts

Right on the other end of the spectrum, we are now seeing bikes hit the market that seemingly cost more than the sum of their parts. This is a big problem in my opinion. I think it shows that the sharp increase in cost for top end bikes has been far out pacing the other price rises that are happening across the industry. There’s a couple of pretty high profile examples of this.

First, is the Cannondale LAB71 SuperSix Evo. It retails at £12,500, but I’ve been able to create an equivalent build for £11k. Unsurprisingly, there are some caveats to that price. Yes, that is by utilising the best prices that I could find for parts on the internet. For example, I found the Dura-Ace groupset for £200 off at one retailer.

Also, I didn’t opt to spec the same wheels as the LAB71 stock build. Instead, I chose some Zipp 303s Firecrests - which some may argue is actually a better wheelset. Also, I wasn’t sure how much their ‘Momo’ bars would cost, so I had to estimate and went for a worst case scenario of £600. I did also factor in a £300 labour charge to cover the cost of having a mechanic build up the bike for you.

The Specialized S-Works Aethos is another example. Here I’m able to save about £350 over the cost of the stock build, and it’s worth highlighting that on this build, I actually specced some Zipp 353 NSW’s which again some would argue are a much better wheelset compared to the Roval Alpinist CLX wheelset that’s found on the stock build. Also, I added in the Roval Alpinist integrated cockpit to really take the build to the next level. If you weren’t to upgrade components then the saving would actually be closer to £1400!

In the case of the LAB71 SuperSix, at full retail pricing, the build came in at £11,700, and that’s still cheaper than the £12,500 asking price of the stock bike, so we really have to wonder, what are we getting for our money at this level? In the lower echelons, it’s more like business as usual, where the bike manufacturers are able to pull on their economies of scale and create bikes which we wouldn’t be able to go out and build ourselves for less money.

Perhaps, even the manufacturers are struggling to buy things for the right price. We have no evidence to support this, but it would provide one explanation as to the obscure situation some top-end bikes have found themselves in.

While I’m sure there will be plenty of comments surrounding the fact that brands are just charging silly money for the sake of it, and you may well be right, I wouldn’t be surprised if they are having to sell at those levels just to maintain the same margins that those products need to achieve to make them commercially viable.

You cannot forget and disregard the impact that Covid, Brexit here in the UK and shipping issues will have had on the cost of some products. Pair that with a struggling world economy and you can have a little understanding. Plus, if there are customers out there who want to buy those bikes, who are we to stop them.

While I understand there could be reasons outside the control of bike brands which mean they have to charge such high prices, I don’t think I’ll be a customer for a bike which I know I can build for less money and also enjoy the opportunity to spec some of my own parts.

Bikes with shoddy quality control

As I’m sure a lot of you know, not all bikes are created equally. Some are created by artisan frame builders who can spend weeks creating a bike which has been handcrafted to perfection. On the other end of the scale, we have bikes which may not have seen quite that same care and attention. Much like my issue with bikes which are too cheap, bikes which are created without the appropriate amount of due care should not be hitting the market.

They will always have inherent problems because if strict manufacturing tolerances aren’t adhered too, the components that then get paired to a defective frame may not operate as they should. Happily, frame facing, which is the process of removing excess material from a frame to ensure a perfect flat surface is achieved, is something that can be done by most mechanics.

Frame facing is something which is important to do anyway as it ensures that when bottom brackets, headsets, brake calipers and the like are bolted to a frame, they are mated to a perfectly flush surface. Also, the process of re-tapping threads is something which can also be done after the frame has been built if needed, but it’s when bikes have deeper, less rectifiable problems that things get serious.

The bottom line is, when considering the energy and materials required to produce a bicycle, manufacturers should be ensuring that it does not go to waste.

Bikes with aluminium deep section wheels

Rolling stock makes a big difference to riding experience

I love riding on semi deep carbon wheels for so many reasons. They look great, they’re generally pretty light, they sound cool and of course, they help you go everywhere faster. It’s rare for a set of these wheels to actually make the experience of riding your road bike any worse.

However, these tend to be wheels that you upgrade to, rather than having them on your bike from stock, unless you’re spending a pretty serious amount of money. My issue lies in the bikes which come with alloy deep section wheels. I can understand why the brands want to fit wheels like these to stock bikes, I’m sure that brands argue that the profile of the rims do offer a speed advantage over box section rims, and I’d be inclined to agree with them.

I’m sure they also fit them so that the much larger tubes of a carbon bike don’t look quite so unbalanced and odd against the wheel choice - and of course, by fitting alloy wheels, they can sell the bike looking as they want it, but offer it at a more affordable price and some may see this as a pretty fair exchange.

For example, Orro sell the Venturi EVO in a 105 specification with Fulcrum DB800 wheels, and it’s hard to deny that on the face of it, the bike does look fast. But to be honest, I would rather opt for a box section rim as it will be lighter and more practical in the short term before I have the chance to upgrade to something that I really want. The extra circa 300 grams you’d have to carry around just to have something that numbs the ride and is harder to spin up just isn’t a good trade-off. Happily, though, wheels are easy to change, so it’s never a terminal problem.

Thank you for reading 20 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

After discovering his love of cycling in college, Sam has always kept two wheels very close. Having spent over five years working in a couple of local bike shops, it's fair to say he enjoys getting hands on. He also loves to push himself to ride ever longer distances and to explore as many new places as possible.

Sam has been Cycling Weekly's video manager since January 2022. You'll find him on our YouTube channel where he brings you the latest cycling tech news, rides, reviews and all of the most important new launches while taking in some incredible cycling adventures too.

-

Hayfever and your riding: how to combat it as the pollen strikes

Hayfever and your riding: how to combat it as the pollen strikesExplanations, medications and holistic measures to make your spring and summer riding more enjoyable

By James Shrubsall

-

I went to Paris-Roubaix Femmes and was shocked at how it is still treated as secondary to the men’s race

I went to Paris-Roubaix Femmes and was shocked at how it is still treated as secondary to the men’s raceThe women’s version of the Hell of the North is five years old, but needs to be put more on equal footing with the men

By Adam Becket