Radical new 3D-printed Mythos Elix stem launches with £500 price tag

British manufacturer claims its high-tech component is the world's first commercially available 3D-printed stem

British brand Mythos has launched what it claims is the world’s first commercially available 3D-printed stem.

Behind the radical-looking Mythos Elix is Dimitris Katsanis, who has worked with British Cycling and Team Sky and whose additive manufactured (3D printed) equipment has already been used to win races at the highest level. Bradley Wiggins used 3D-printed titanium custom bars made by Katsanis to break the world Hour Record in 2015.

The Mythos Elix is made not from titanium but from Scalmalloy, a metal alloy made with scandium, aluminium and magnesium that was developed for 3D printing by Airbus. Scalmalloy has a high strength that makes it ideal for aerospace and professional cycling applications.

The skeleton-like appearance of the Mythos Elix is down to the ability of the 3D printing process to, in Mythos’s words, “eliminate areas of high stress with small local reinforcements, and reduce weight around other areas by skilfully removing any non-essential material. Not only that, but the fact that all of this happens in-house, without the need for any part-specific tooling, means that we can create one-off products and prototypes in days that would normally take months.”

Mythos claims that with the Elix stem it has been able to significantly improve the useful stiffness - 15% torsionally stiffer than an equivalent alloy stem - and "implement a new contemporary design."

3D printing might not have had the best press in the last year, with a base bar used by the Australian team pursuit squad failing dramatically at last year’s Olympics. It emerged that the particular components hadn’t been made to the correct specification and that 3D printing itself wasn’t at fault. However, Mythos supplies a detailed description of its manufacturing process starting at the beginning.

“Additive manufacturing (3D printing) works by adding layers of powdered material and melting that powder to our design. This builds up layer by layer meaning we can tailor our design to have features that can’t be replicated using traditional manufacturing methods like CNC machining.

There’s also a reassuring paragraph on testing.

“To arrive at this design we essentially started with testing. Using a manual topology optimisation method we switched between FEA (Finite Element Analysis) simulations and CAD software to identify load paths and therefore areas that needed more or less material, and then made those changes iteratively.

“This method is what allowed us to increase the stiffness of the stem in torsion without affecting the bending stiffness. Once the final design was approved and passed our FEA stress analysis, prototypes for each size were printed and fatigue tested using the test methods outlined in the ISO 4210 test standard. Prototypes were also sent out to a selection of riders around the world, who have ridden the stem on road, gravel, and even to a win at the second race of the 2022 Italian Fixed Cup.”

The stems are all produced in Britain and are available in all sizes - as you’d expect of a 3D printed component - and available from Mythos's website.

The Mythos Elix's price of £500 puts it up there with the most expensive stems on the market. The widely available carbon THM Tibia stem costs £459 while the AX-Lightness Rigid stem costs €529.

A stem that Bastion produced for the Australian Argon 18 bikes for the Tokyo Olympics (not the ill-fated base bar) had a price tag of AU$2,040, equivalent to $1,450 or £1,152.

Specifications of the Mythos Elix stem are:

- Material: Scalmalloy®

- Length: 100-130mm

- Rise: +/- 8 degrees

- Clamp Diameter: 31.8 mm

- Hardware: Titanium M5 x 16 mm

- Stack Height: 45mm

- Weight: From 150g

- Compatible with FSA ACR Integrated Cockpit System

- Internal cable routing compatible

- Price: £500

Thank you for reading 20 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

Get The Leadout Newsletter

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Simon Smythe is a hugely experienced cycling tech writer, who has been writing for Cycling Weekly since 2003. Until recently he was our senior tech writer. In his cycling career Simon has mostly focused on time trialling with a national medal, a few open wins and his club's 30-mile record in his palmares. These days he spends most of his time testing road bikes, or on a tandem doing the school run with his younger son.

-

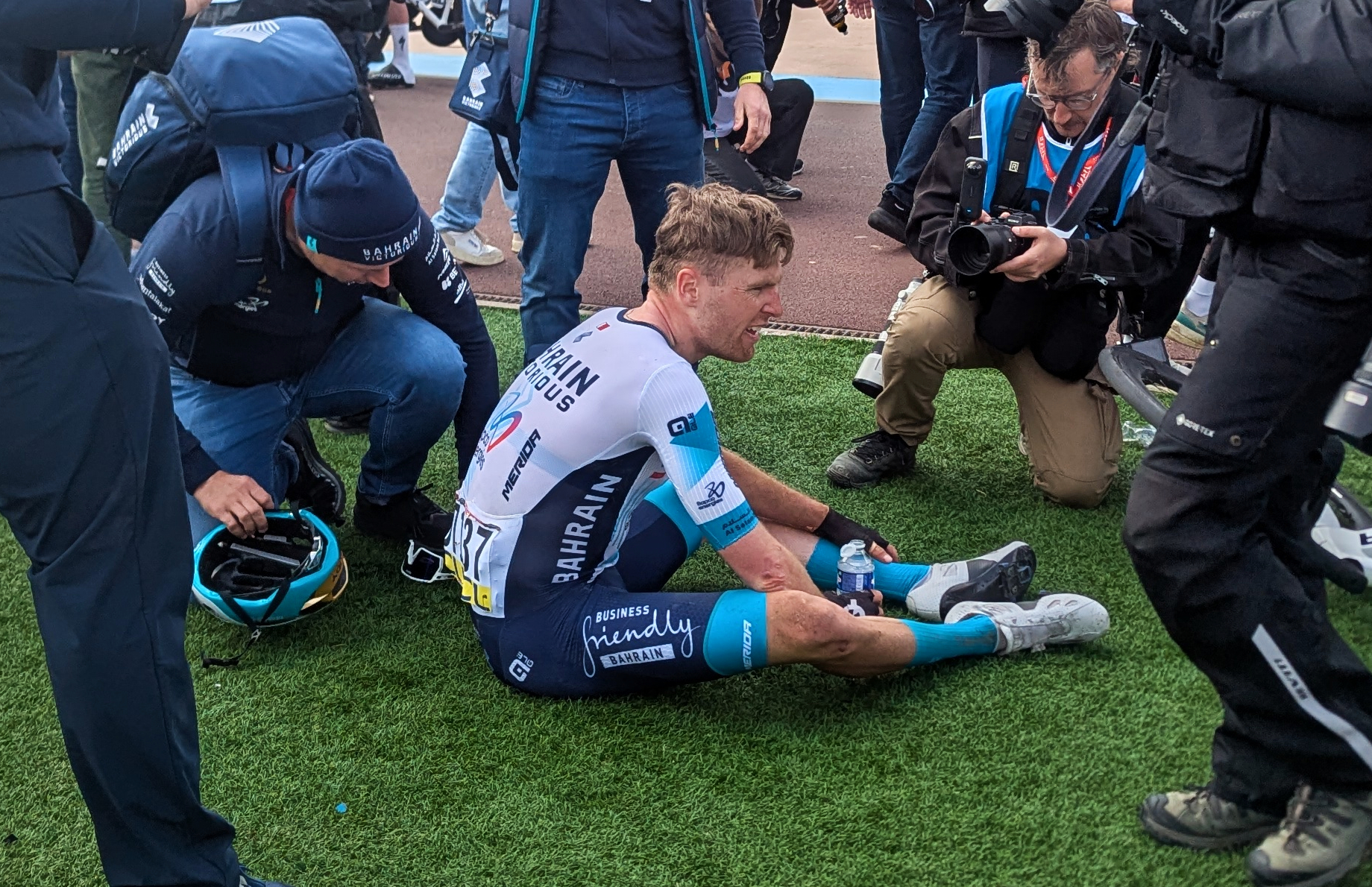

'I'll take a top 10, that's alright in the end' - Fred Wright finishes best of British at Paris-Roubaix

'I'll take a top 10, that's alright in the end' - Fred Wright finishes best of British at Paris-RoubaixBahrain-Victorious rider came back from a mechanical on the Arenberg to place ninth

By Adam Becket Published

-

'This is the furthest ride I've actually ever done' - Matthew Brennan lights up Paris-Roubaix at 19 years old

'This is the furthest ride I've actually ever done' - Matthew Brennan lights up Paris-Roubaix at 19 years oldThe day's youngest rider reflects on 'killer' Monument debut

By Tom Davidson Published